You’ve chosen isononanoic acid for its superior performance. Now you face a bigger challenge: finding a supplier you can trust. A wrong choice can lead to production-halting delays.

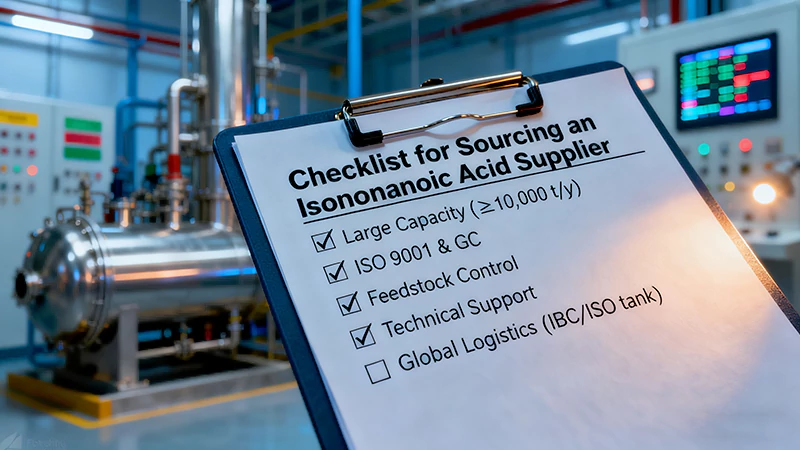

A reliable isononanoic acid supplier must have significant production capacity, stringent quality control (ISO 9001), control over their feedstock, robust technical support, and a global logistics network. These factors ensure supply chain stability and consistent product quality for your critical formulations.

A checklist on a clipboard in a modern chemical plant setting.

In the previous articles in this series, we’ve explored the powerful chemical principles of isononanoic acid (INA) in creating next-generation lubricants and coatings. But specifying this high-performance molecule is only half the battle. The most brilliant formulation is worthless if you can’t get a consistent supply of high-quality raw material. From my experience, choosing a supplier is as critical as choosing the chemical itself. A supplier isn’t just a vendor; they are a partner in your success. A great partner ensures your production lines keep running, while a poor one can become your single biggest point of failure. This checklist is designed to help you vet potential suppliers and build a resilient, high-quality supply chain.

How Critical is Production Capacity for Supply Chain Security?

Your supplier accepts your large order, but then can’t fulfill it on time. Your production line grinds to a halt, you miss customer deadlines, and your reputation suffers.

Partner with a supplier who has massive, scalable production capacity. A large capacity isn’t about bragging rights; it’s your insurance policy against supply disruptions and your guarantee that the supplier can grow with you.

An aerial view of a large, modern chemical manufacturing facility.

When you’re sourcing a critical raw material like isononanoic acid, the supplier’s nameplate capacity is one of the first numbers you should look for. A small, boutique producer might be adequate for R&D samples, but when you move to full-scale production, you need a partner with industrial might. Look for a supplier with an annual production capacity in the tens of thousands of tons. For example, a capacity of 10,000 tons per year signals several crucial things to a buyer. First, it demonstrates a deep commitment to the market and the molecule. Second, it means they can easily handle large-volume contracts without their other customers feeling a pinch. Third, and most importantly, it provides a buffer. In a world of unpredictable geopolitical events and fragile supply chains, a large producer has the scale to absorb shocks, manage inventory strategically, and ensure a steady flow of material. From my perspective as a formulator, knowing my supplier has this level of capacity means I can sleep at night. It removes a major variable from my risk assessment. It means that when my company lands a huge new contract, I don’t have to worry if my INA supplier can keep up. This is especially vital for INA, which is used in mission-critical applications like aviation lubricants and long-life coolants where supply continuity is non-negotiable.

Beyond the Spec Sheet: What Defines True Product Quality and Consistency?

A new batch of INA arrives “in-spec,” but it ruins your formulation. Your lubricant’s viscosity is off, or your coating’s color is wrong. You’ve wasted time, material, and money.

True quality is batch-to-batch consistency, verified by rigorous quality control. A top-tier supplier uses advanced analytics to ensure high purity (>99%) and a consistent isomer distribution, all managed under an ISO 9001 certified system.

A chemist analyzing a sample with a Gas Chromatography (GC) machine.

The Certificate of Analysis (CoA) tells you a batch meets a set of minimum specifications. It doesn’t tell you the whole story. For a complex molecule like isononanoic acid, true quality lies in consistency. The specific mix of isomers in INA can affect the final properties of your product. For example, in polyol esters, the isomer distribution influences low-temperature fluidity and pour point. In alkyd resins, trace impurities not listed on a basic CoA can affect color, drying time, and long-term yellowing. This is why you must dig deeper than the spec sheet.

The Hallmarks of a Quality-Obsessed Supplier

A supplier dedicated to quality will be transparent about their process. Here’s what to look for:

- Advanced Analytical Capabilities: Do they rely solely on simple tests like acid value and color, or do they use more sophisticated methods like Gas Chromatography (GC)? GC is essential for verifying the purity (ideally >99%) and, more importantly, for ensuring the profile of isomers is consistent from one batch to the next.

- ISO 9001 Certification: This isn’t just a piece of paper. An ISO 9001 certification means the supplier has a robust, documented Quality Management System (QMS). It ensures traceability, documented procedures for handling non-conforming material, and a culture of continuous improvement. It’s an externally audited guarantee that they are serious about quality.

- Traceability: Can the supplier trace a specific batch all the way back to the raw materials used to make it? This is crucial for any root cause analysis if a problem does occur.

In my experience, a supplier who openly discusses their QC methods and proudly displays their ISO certification is one who understands that their product’s consistency is the foundation of their customer’s success.

How Can a Supplier Ensure Price and Supply Stability?

Your INA price suddenly spikes due to market volatility, or your supply is cut off without warning. Your budget is blown, your product becomes uncompetitive, and you’re left scrambling for answers.

Choose a supplier with a robust sourcing strategy and strong, long-term partnerships with world-class producers. This strategic approach provides superior price stability, risk mitigation, and a more secure supply chain than relying on a single source.

Strategic partnerships are the foundation of a resilient chemical supply chain.

In the complex global chemical market, the idea of a single, self-contained source can be misleading. True supply chain resilience comes from strategic relationships and market intelligence. A supplier’s ability to provide stable pricing and an uninterrupted flow of material is not necessarily tied to in-house manufacturing, but rather to the strength and diversity of its sourcing network. A supplier who is merely a spot-buyer is subject to the full force of market volatility, passing every price swing and shortage directly on to you. In contrast, a strategic supplier operates as a hub, leveraging deep connections with the industry’s best producers to create a stable and reliable supply channel for their customers. This model transforms the supplier from a simple reseller into a crucial risk-management partner for your business.

The Strength of Strategic Partnerships

A supplier with long-term, high-volume contracts with major producers isn’t just another customer; they are a strategic channel partner. This “VIP” status grants them several advantages that directly benefit you:

- Priority Allocation: During times of market tightness or shortages, producers will prioritize their strategic partners, ensuring their supply lines remain open while others may be cut off.

- Pricing Stability: Long-term contracts and large purchasing volumes allow the supplier to negotiate favorable terms and buffer their customers from short-term price spikes. They can offer more predictable, stable pricing that makes your own budgeting and product costing far easier.

- Market Intelligence: Being deeply integrated with key producers gives your supplier unparalleled insight into market trends, planned maintenance shutdowns, and potential disruptions. They can act as your advisor, helping you make smarter purchasing decisions and manage your inventory proactively.

Risk Mitigation Through a Diversified Network

Relying on a single manufacturing plant, even a large one, creates a single point of failure. A fire, a natural disaster, or a regional logistical snarl can halt production instantly. A truly resilient supplier mitigates this risk by maintaining strong relationships with multiple world-class producers across different geographic regions. This diversification is your ultimate insurance policy. If one source experiences a disruption, your supplier has the agility to pivot and secure material from their other partners, ensuring your production continues without a hitch. Asking a potential supplier, “Describe your relationships with your manufacturing partners,” is one of the most important questions you can ask. A detailed answer reveals a sophisticated strategy built for stability and reliability.

When Formulations Go Wrong, Is Your Supplier a Partner or Just a Vendor?

You’re having trouble integrating INA into a new formula, and the data sheet isn’t helping. You’re wasting valuable R&D time and resources on frustrating trial and error.

Partner with a supplier who offers expert technical support. A great supplier acts as a formulation partner, providing the expertise to help you troubleshoot issues and optimize your use of their product.

A team of chemists collaborating in a research and development lab.

The product you buy is the isononanoic acid. The value you receive should be much more than that. In my career, the suppliers who have earned my long-term loyalty are the ones who act as an extension of my own R&D team. A commodity vendor just sends you a drum and a bill. A true partner helps you succeed with their material. When you’re vetting a supplier, you need to assess the quality of their technical service. What does good support look like? It’s the ability to pick up the phone and talk to a chemist or engineer who deeply understands the product and its applications. It’s getting help with questions like:

- “I’m developing a new polyol ester for a refrigeration application. Based on your INA, what starting formulations can you recommend?”

- “We’re seeing a slight color shift in our alkyd resin. Can you help us review our process and your CoA data to troubleshoot?”

- “We want to create a high-solids, low-VOC coating. What’s the optimal level of your INA to use as a chain stopper to hit our target viscosity?”

A supplier with strong technical backing can save you weeks or even months of development time. They can provide starting-point formulations, share performance data, and offer insights that you won’t find on any data sheet. This level of support transforms the supplier relationship from a simple transaction into a strategic partnership. Before you sign a contract, ask to speak with their technical team. Their knowledge, responsiveness, and willingness to help will tell you everything you need to know about the company’s culture and their commitment to your success.

Can Your Supplier Deliver? Assessing Global Logistics and Packaging Options

Your critical shipment of INA arrives late, in damaged packaging, or in a format that’s difficult for your team to handle. This disrupts your production schedule and creates safety and operational headaches.

A reliable global supplier must offer flexible packaging options (e.g., IBC totes, drums, ISO tanks) and have a proven logistics network to ensure timely, safe delivery to your facility.

Various chemical packaging options: ISO tank, IBC totes, and HDPE drums.

The final, and perhaps most practical, piece of the puzzle is logistics. A supplier can have the best product in the world, but it’s useless if they can’t get it to you safely, on time, and in the right format. This is especially true for global operations, where you might be sourcing from one continent and manufacturing on another.

Key Logistical Questions to Ask:

- What are your packaging options? A flexible supplier should offer a range of choices to fit your operational needs. Do you need 200 kg steel drums for smaller batches? 1000 kg Intermediate Bulk Containers (IBCs) for easier handling in a mid-sized plant? Or are you a large-volume user who can benefit from the efficiency and cost-effectiveness of ISO tanks? The right packaging minimizes handling, reduces waste, and improves safety.

- What is your experience with international shipping? A seasoned global supplier will have a dedicated logistics team that understands the complexities of customs, import/export regulations, and international freight. They should have established relationships with reliable shipping lines and be able to provide clear communication and tracking information throughout the process.

- What is your lead time and on-time delivery rate? Ask for metrics. A professional supplier should be able to tell you their average lead time to your region and provide data on their on-time delivery performance. This transparency is a sign of a well-managed supply chain.

In short, scrutinize their logistics capabilities as thoroughly as you scrutinize their product quality. A supplier who has invested in a robust, flexible, and global logistics network is one who understands that their job isn’t done until the product is safely inside your facility.

Conclusion

Choosing an isononanoic acid supplier is a strategic decision that impacts your product quality, operational efficiency, and business resilience. By using this checklist to evaluate potential partners on capacity, quality, vertical integration, technical support, and logistics, you can build a secure and reliable supply chain for this critical material.

References

-

- ISO 9001 Quality Management: International Organization for Standardization.

-

- Vertical Integration: Investopedia.

-

- Supply Chain Management (SCM): Optimizing Engineered Fluids with Isononanoic Acid.